- Model:LT series

- Capstan diameter:max 650mm

- Number of drawing pass:25

- Motor power:max 75kw

- Max speed:600m/min

Heavy wet wire drawing machine is only Chinese’s made, no other countries make such type machine. Our heavy wet wire drawing machine, through continuous innovation, optimization design, having a stand on our own intellectual property.

Product Description

1.Heavy wet wire drawing machine

Heavy wet wire drawing machine is only Chinese’s made, no other countries make such type machine. Our heavy wet wire drawing machine, through continuous innovation, optimization design, having a stand on our own intellectual property. Machine can equip Spool take-up machine , and also have feature like :wire drawing machine gearbox assembly parts, Pulley piece structure of wire drawing machine, Waterproof device of wet wire drawing machine.

Reducer of the machine applies 8-module herringbone ,gear of take-up box is 10-module with speed ratio of 1:1. High-speed gear shaft material is 40 Cr with high-frequency quenching, the round tower according to the user needs to be divided into: common ZG55 cast steel, common ZG55cast steel with high-frequency quenching, common ZG55 cast steel with tungsten carbide coating. Transmission bearings all adopt famous brand products, take-up transmission system coupling sub-installation, the axis of the stress distribution is reasonable. Reducer box, water tank, take-up box are installed in the same base for easy installation and lifting. Surface of the water tank is painted high grade and quality paint, inside and outside of the electrical cabinet both use plastic-spraying process. It is divided into common control and frequency control. The electrical components used in all Chinese or international famous brand products.

Heavy water wire drawing machine is one of our products with more than 20% market share of China and 50% market share of key districts. We will make unremitting pursuit of high quality, suitable price for this machine, and contribute to metallic industry.

Attention to detail, innovation of key technology, is always our technical route. Consciously ‘customer first’ become conscious of social responsibility, diligently climb, in order to form a comprehensive coverage of patent technology.

Description

(1) Cooling and lubrication conditions are particularly good, favorable quality of finished steel

(2) In the small cabinet to complete the multi-pass drawing, compact structure, small occupation

(3) Excellent working conditions, after drawing steel smooth surface cleaning, can guarantee the quality of galvanized steel wire

(4) Wet drawing machine is suitable for drawing fine wire.

(5) As the wet drawing machine for drawing friction sliding, consumption of motor power. In addition, the mold, and die technology by high demand.

|

Items |

Unit |

LT8/650-560 |

LT11/650-560 |

LT13/650-560 |

LT15/560-500 |

LT17/560-500 |

LT11/450 |

LT13/450 |

LT15/450 |

LT17/450 |

|||

|

Capstan diameter |

mm |

650-560 |

650-560 |

650-560 |

650-560 |

560-500 |

450 |

450 |

450 |

450 |

|||

|

Drawing dies |

time |

8 |

11 |

13 |

15 |

17 |

11 |

13 |

15 |

17 |

|||

|

Max inlet wire diameter |

mm |

Ф8-6.5 |

Ф8-6.5 |

Ф8-6.5 |

Ф6.5-5.5 |

Ф6.5-5.5 |

Ф4.5 |

Ф4.5 |

Ф4.5 |

Ф4.5 |

|||

|

Min outlet wire diameter |

mm |

Ф3.7-3.0 |

Ф2.7-2.2 |

Ф2.5-2.0 |

Ф1.6-1.4 |

Ф1.4-1.2 |

Ф1.7 |

Ф1.4 |

Ф1.2 |

Ф1.0 |

|||

|

Drawing speed |

m/min |

200 |

250 |

250 |

280 |

280 |

260 |

280 |

300 |

300 |

|||

|

Inlet tensile strength |

Mpa |

≤1150 |

≤1150 |

≤1150 |

≤1150 |

≤1150 |

≤1150 |

≤1150 |

≤1150 |

≤1150 |

|||

|

Total compression rate |

% |

78.70 |

88.54 |

90.53 |

93.94 |

95.36 |

85.73 |

90.23 |

92.89 |

95.06 |

|||

|

Average compression rate |

% |

17.58 |

17.88 |

16.58 |

17.05 |

16.52 |

16.22 |

16.44 |

16.16 |

16.22 |

|||

|

Motor power |

Kw |

160-132 |

160-132 |

160-132 |

132-110 |

132-110 |

90 |

75 |

75 |

75 |

|||

|

Dimension |

mm |

5800x2350x1800 |

5500x2200x1600 |

||||||||||

|

Weight |

t |

11 |

11 |

11 |

11 |

11 |

9.5 |

9.5 |

9.5 |

9.5 |

|||

2.Medium/light wet wire drawing machine

This equipment is suitable for drawing high, medium, low carbon steel wire. The usage scope is for steel wire rope, spring wire, bead wire, galvanized wire, etc.

Features: Compact structure, small occupation, complete multi-pass drawing in the small cabinet, high total compression rate, without reverse phenomenon when drawing, high drawing speed; Cooling and lubrication conditions are particularly good, favorable quality for finished steel. Compared with the same type turnover wire drawing machine, it shares the advantages as lower investment cost, lower operation cost and higher economic benefit.

We had the new patent technology and exclusive intellectual property rights which ensure our machine are high-efficiency, energy-saving, environmental-friendly. We are a leading manufacturer with high-quality and warmly service.

Main technical parameters|

Items |

Unit |

LTA11/350 |

LTA13/350 |

LTA15/350 |

LT15/350 |

LT17/250 |

LT19/200 |

|

Capstan diameter |

mm |

350 |

350 |

350 |

350 |

250 |

200 |

|

Drawing dies |

time |

11 |

13 |

15 |

15 |

17 |

19 |

|

Max inlet wire diameter |

mm |

Φ3.5 |

Φ3.5 |

Φ3.5 |

Φ2.8-2.2 |

Φ2.2-1.20 |

Φ1.2-1.0 |

|

Min outlet wire diameter |

mm |

Φ1.5 |

Φ1.3 |

Φ1.1 |

Φ0.9-0.7 |

Φ0.65-0.35 |

Φ0.3-0.25 |

|

Drawing speed |

m/min |

280 |

300 |

330 |

420 |

420 |

600 |

|

Inlet tensile strength |

Mpa |

≤1150 |

≤1150 |

≤1150 |

≤1150 |

≤1150 |

≤1150 |

|

Total compression rate |

% |

81.63 |

86.20 |

90.12 |

89.67 |

89.67 |

93.75 |

|

Average compression rate |

% |

14.28 |

14.13 |

14.3 |

14.04 |

14.04 |

13.58 |

|

Motor power |

KW |

55 |

55 |

55 |

45-37 |

15-37 |

7.5-11 |

|

Dimension |

KW |

4500x1600x1500 |

4000x1500x1400 |

2800x1100x800 |

|||

|

Weight |

T |

4 |

4 |

4 |

3 |

2.8 |

1.5 |

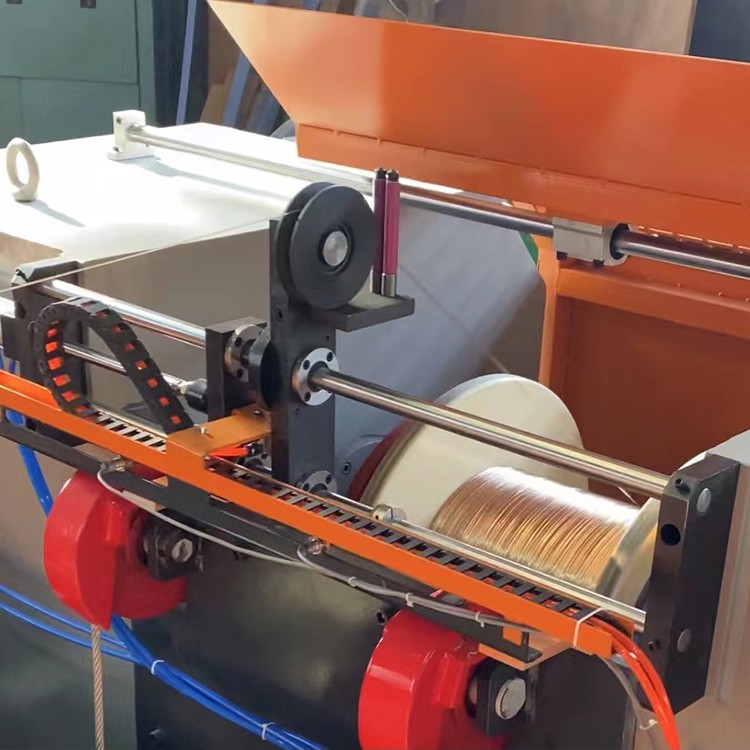

3.Fine wet wire drawing machine

This product is new equipment for solar photovoltaic industry, mainly applicable for precision fine drawing machine high carbon steel wire with micro-diameter, the most professional sawing machine for sawing silicon wafers.

The host has 25 dies 6 shafts, it can realize multi pass, high compression rate, low part compression rate one side high speed drawing. It is very easy and convenient to operate the auto-lifting value wet wire drawing machine.

Machine uses AC frequency and digital control, wire drawing and winding synchronous follow, take-up can keep the wires in order accurately, intelligent detect wire status, automatic compensation for instantaneous adjustment, make sure the cutting wires is in a precise and orderly state. The whole machine is equipped with most mature control technology, especially with the most advanced total automatically take-up technology, and with our more than 10 years professional manufacture experience.

4.Turnover wet wire drawing machine

Turnover wet wire drawing machine manufactured byus is applicable for high speed drawing of steel wire rod, hose wire, galvanized wire, wire rope and stainless steel wire.

Features: Compact structure, turning lightweight, easy operation. Uses AC variable frequency speed regulation, controlled by PLC, wire drawing and winding synchronous follow, realize constant winding. It can use different size spool take-up machine, suitable for SG120, SG165, SG195, SG299, SG200, SG255, SG300 and other sizes wire spool.

Our turnover wet wire drawing machine is the metal products industry’s technological progress replacement.